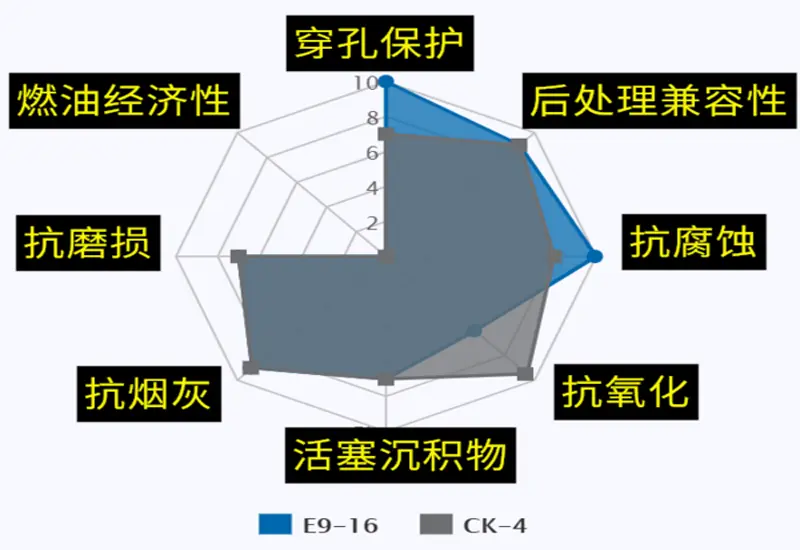

To meet the China VI emission standards, our trucks are equipped with a DPF in their exhaust treatment equipment to ensure emissions meet the standards. Not all particulate matter trapped in the DPF is burned, leaving some incombustible material, known as ash. Engine oils specifically designed for China VI engines, with low-ash additives, ensure maximum protection for the exhaust treatment system while maintaining engine lubrication performance.

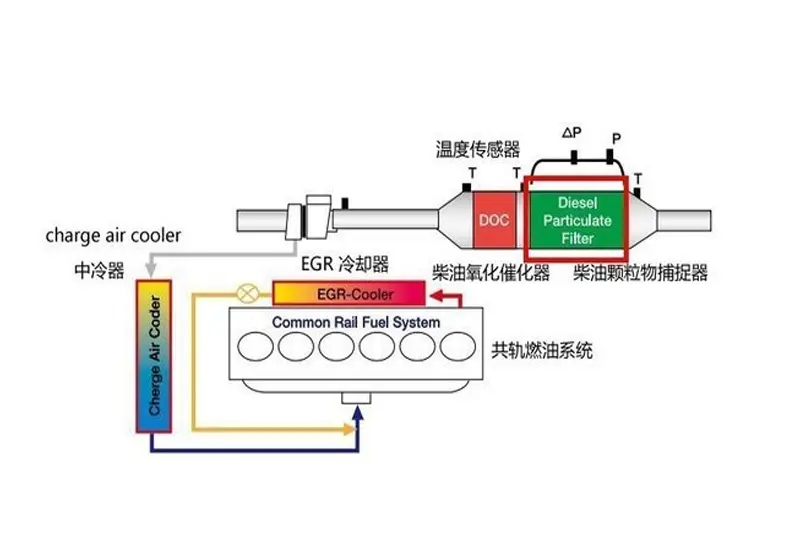

To meet the China VI emission standards, trucks must undergo a series of improvements to reduce exhaust emissions. Many truck drivers may have noticed that China VI trucks have larger exhaust after-treatment systems and multiple exhaust gas sensors on the exhaust pipe. This is due to the stricter emissions standards and the increased complexity of exhaust after-treatment.

New standards and new technologies require new maintenance methods, and existing maintenance methods must also evolve with the times. In today’s Truck Encyclopedia, we’ll discuss the basic maintenance requirements for China VI engines.

Our trucks mostly use diesel as fuel. Diesel exhaust emits components such as carbon monoxide, carbon dioxide, and various nitrogen oxides, as well as particulate matter. Because the China VI emission standards have stricter limits for PM (fine particulate matter), trucks must be equipped with a diesel particulate filter (DPF) in their exhaust treatment systems to meet these standards. Since this exhaust treatment system is expensive, proper use and maintenance of the DPF is essential for China VI vehicle owners.

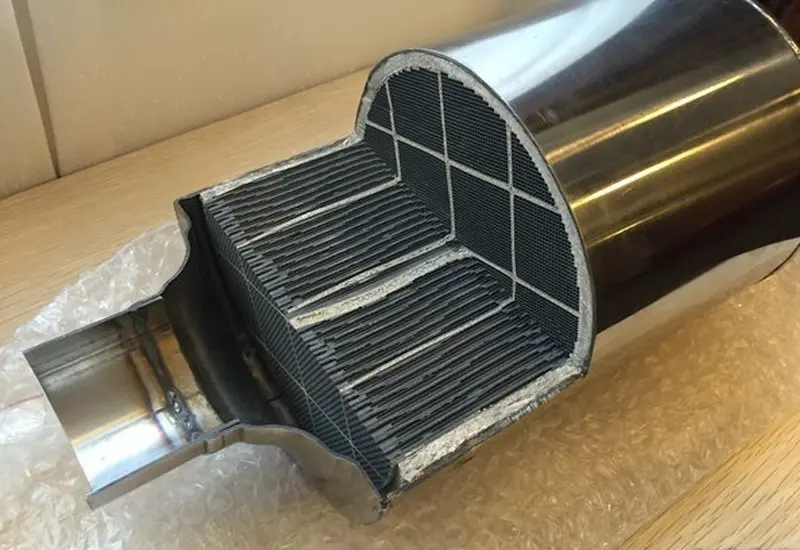

The DPF, standing for diesel particulate filter, prevents particulate matter produced by diesel engines from entering the atmosphere. In layman’s terms, the DPF functions like a filter, intercepting various particulate matter in engine exhaust, primarily carbon particles, commonly known as black smoke.

However, as the DPF ages, it can become clogged with carbon particles, increasing engine exhaust backpressure and reducing power and fuel efficiency. This necessitates clearing the air space within the DPF, a process known as DPF regeneration. DPF regeneration typically involves active or passive regeneration, typically using high-temperature combustion.

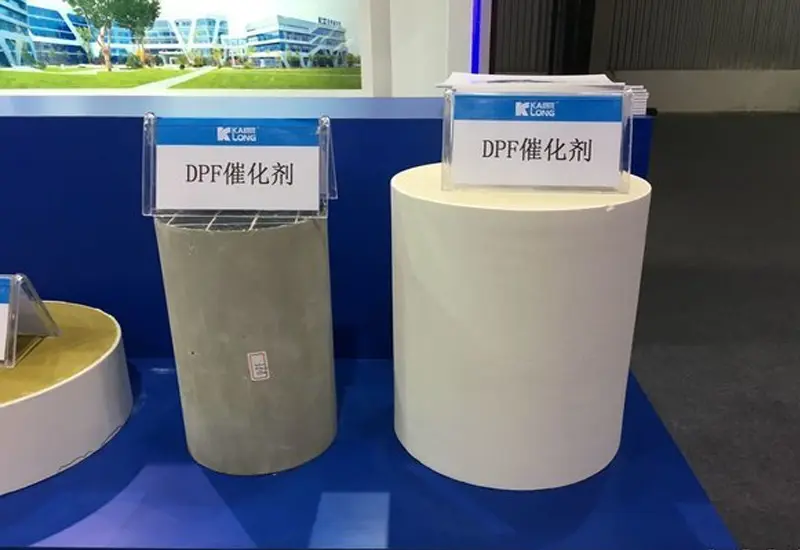

However, not all particulate matter trapped in the DPF is burned; some incombustible matter, known as ash, remains.

When it comes to ash, it can be simply understood as inorganic matter. At high temperatures, organic components evaporate, while inorganic components remain, a residue known as ash.

The ash in truck exhaust aftertreatment systems primarily comes from engine oil additives, engine metal debris, and metal components in diesel, with the primary source being engine oil additives.

Now that the principles and causes of failure have been explained, truck drivers of China VI emission-compliant vehicles should take note. To protect your expensive exhaust aftertreatment system, you must use engine oil that meets the manufacturer’s China VI standards.

At the same time, we must firmly say no to roadside oil spills. This way, our trucks can maintain long-term proper operation and continue on the road to profitability.