Whenever a new engine technology is released, we often marvel at its horsepower, torque, fuel efficiency, and so on, but few people pay attention to how to maintain it.

▎Environmental protection continues to intensify, and technology becomes increasingly complex

my country implemented the National IV emission standard on July 1, 2013, followed by the National V on January 1, 2017, and the National VI emission standard is about to be fully implemented. Each upgrade in standards has imposed stricter requirements on truck emissions.

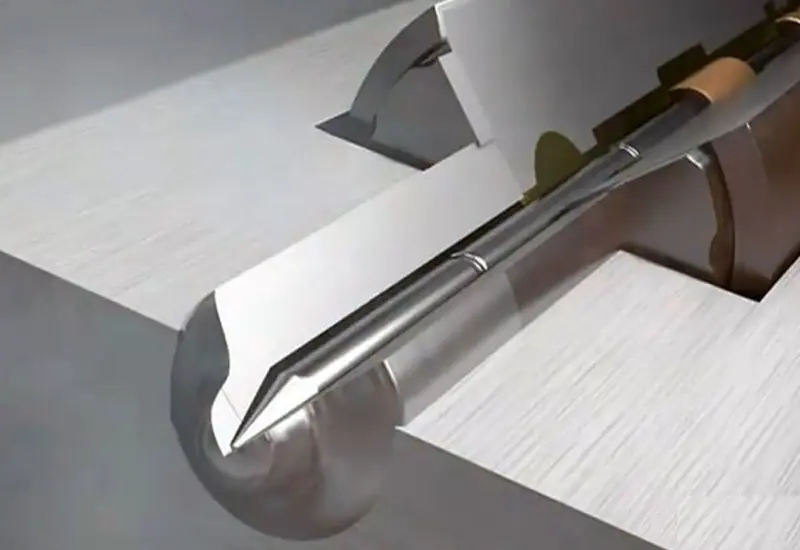

To meet these stringent requirements, the injection pressure of our diesel engines has become increasingly higher. Some vehicles are now equipped with diesel common rail systems with an injection pressure of 2500 bar. However, this is not enough. Various exhaust treatment technologies, such as EGR, DPF, SCR, and SOC, must work together to meet emission standards.

But simply having these technologies alone is enough to meet emission standards. As the lifeblood of the engine, motor oil must also continuously evolve to adapt to new engine technologies.

Maintenance concepts need updating; the old ways won’t cut it.

▎Exhaust gas treatment systems are more sophisticated and valuable.

In our previous article, “Truck Encyclopedia: Good Engine Oil Performance Depends on Additives,” we explained that older engine oils contained numerous extreme pressure additives for wear resistance.

These additives, composed of phosphorus, zinc, organic tungsten, and molybdenum disulfide, can affect the emission system after high-temperature combustion, causing “poisoning” of the exhaust catalytic converter, especially in vehicles meeting the China V and China VI emission standards.

Therefore, in the China V and China VI era, to protect our exhaust gas treatment systems, both API and ACEA have introduced more environmentally friendly and exhaust gas treatment-friendly engine oils.

A comparison of the characteristics of engine oils meeting the China II CF-4 standard and the China VI CK-4 standard reveals that CF-4 made no investment in aftertreatment system compatibility, fuel economy, or oxidation resistance, focusing solely on basic anti-wear, anti-corrosion, and cleanliness. However, by 2015, CK-4 engine oil had significantly improved aftertreatment system compatibility.

▎ Popularization of Long-Lasting Technologies

At the same time, with the increasing adoption of various extended oil change technologies, truck maintenance intervals have also been extended, placing higher demands on engine oil. Beyond basic wear protection, delayed maintenance intervals also place higher demands on engine oil durability and cleanliness.

The 2016 CK-4 standard, based on the 2006 CJ-4 standard, offers the following:

1. Improved oxidation stability.

2. Improved aeration capacity.

3. Improved wear protection.

4. Improved shear stability.

5. Improved fuel economy.

6. Minimum HTHS viscosity of 3.5 cP (better oil film strength).

7. Compatible with existing and new diesel engines.

8. CK-4 offers lower viscosity oils (5W, 10W).

The good news is that these features of the new engine oil standard are directly compatible with older engines.

That is to say, when we purchase engine oil, if conditions permit or the prices are similar, we should try to choose engine oil with newer standards to better protect our engine.